Our knowledge

Our French Savoir-Faire

Our cooperative, Les Celliers Associés, has developed unique cider know-how over more than 65 years, combining both tradition and innovation.

Brittany is one of the largest cider-producing areas, due in particular to the local climate and the soil type, conducive to rich cider apples, full of sweetness and aromas.

Producers & the entire Val de Rance Team have been working together with dedication and authenticity since 1963.

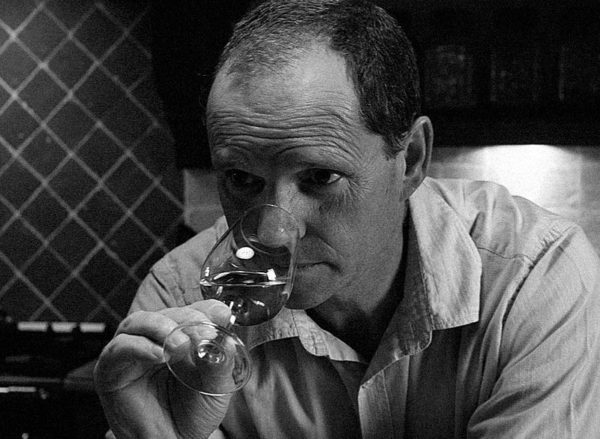

Our cellar master

Alain Lepage is our Cellar Master. He selects the best varieties of cider apples and ensures that every stage of the process conforms to our requirements. He selects all the apples that come from our orchards and checks the quality of every blend.

Some words from our Cellar Master, Alain Lepage:

“Each type of cider, whether dry, sweet or rosé, is made from a specific vintage. I created the recipes with the whole team. Cider is a living product; we create a new balance each time, between colour, slight bitterness, alcohol content and effect on the palate.

1. Apple supply:

The apples are harvested in the orchards of our producers from September to December and then transported to us.

2. Cleaning and crushing of apples:

Once the apples are delivered, they are pushed into the water channels that take them to the cleaning machine. They are then crushed and moved to a macerator for 1 hour to enhance their aromas

3. Pressing:

Once apples are macerated, they are sent to a press with a capacity of 15 tons of apples. All the juice is extracted and led to a clarification tank where it will macerate for 10 days at 5°C. The remaining apple pulp is dried in tanks at up to 140°C and sold on to animal feed companies.

4. Fermentation

In the vats, the heavier impurities are separated from the clear apple juice. A gas called “Chapeau Brun” is the natural gas that emanates from apple pectin that will also be extracted from the juice. . The clear juice is then transferred to a tank for natural fermentation, which lasts between 4 and 8 weeks and during which the sugar turns to alcohol. It finishes with a centrifugal stage which also removes the yeast.

5. Blending the various apple flavours:

Blending is the combination of several different clear apple juices. Before blending, the juices are filtered to obtain the clearest cider possible.

6. Bottling

Before bottling, the bottles are cleaned and checked according to our specifications. They are then filled by an automatic head and corked. Once bottled, they are pasteurised, labelled and stored to optimise their shelf–life.

Cider-making FAQs

What is a maître chai?

A maître chai is the person who precisely selects apple varieties and creates a cider recipe from them, using a blend of juices.

A maître chai will also ensure that the various stages of cider production are respected, from pressing to extract the juice from the apples, to fermentation and bottling.

How to make apple cider

Apple cider is made in 6 stages

Receiving the apples

Washing and brushing the apples

Pressing

Fermentation of the cider

Blending

Bottling.

These stages can be supervised by a Maître Chai.

When are cider apples harvested?

Apples for cider are harvested from orchards by growers in the autumn, from September to December.

How long does the juice macerate when making apple cider?

After crushing, the apples are macerated for 1 hour. After pressing, the apples are macerated a 2nd time for ten days at 5°C.

What is cider fermentation?

Cider fermentation is the 4th stage (of 6) in the cider-making process. It transforms sugar into alcohol. It is fermentation that gives the juice its characteristic taste.

What happens before the cider is bottled?

Several stages take place before the cider is bottled:

Receiving the apples

Washing and brushing the apples

Pressing

Fermentation of the cider

Blending

Bottling.